We are proud to be a certified International Safe Transit Association (ISTA) facility. We proactively manage the safety and sustainability of each step of the packaging and delivery process to provide efficient, safe and sustainable printing and packaging solutions.

What Is Structural Packaging Design?

Structural packaging design — or physical packaging enhancement — refers to the industrial design of a product’s packaging, including its shape, materials and imagery. Exceptional structural packaging design differentiates your products from your competitors and provides a host of benefits to the customer.

It plays a crucial role in the safe delivery of products, your brand’s perception and the end user’s product experience. Protect your brand’s reputation with innovative and sustainable packaging designs.

To ensure package integrity, we test our packaging in our ISTA 6 test lab using compression, vibration and incline tests.

Why Is the Structural Design of a Package Important?

The structural design of a package protects your products, demonstrates brand identity and provides a memorable unboxing experience for customers in several ways:

- Structural Integrity: Packages too large or small could damage products during transit. Your packaging’s design should custom-fit your products to ensure they arrive undamaged and intact.

- Brand Identity: Design evokes emotion and builds brand loyalty. Branded packaging makes your products stand out from competitors’ products and demonstrates your brand’s values in an unforgettable, beautiful way.

- Memorability: Celebrate seasonal or promotional products with custom packaging designs. A unique packaging design highlights the importance of a product and offers a memorable unboxing experience for your customers.

Some of the Types of Packaging Designs

Packaging designs and methods serve unique roles in storage, shipping and product display. The most common types of packaging designs and methods are:

Case Pack Packaging

The case pack packaging format involves bundling multiple units of the same product into a single master case for storage and shipping. Common case pack structures are regular slotted cartons, die-cut cases and partitioned cases. Popular types of master cases include corrugated boxes, rigid boxes, telescopic boxes and wooden crates.

This packing method streamlines inventory management and logistics. It also increases handling efficiency and provides strong product protection during transit and against rough handling. Case packing is commonly used in club store packaging applications, food and beverage packaging, wholesale distribution and retail supply chains.

Flat-Pack Packaging

Flat-pack packaging involves packing items in a flat or compact form. It typically contains disassembled or collapsed products, assembly instructions and additional hardware. Flat packing saves space during shipping and storage. This method also improves warehouse efficiency while reducing freight and warehousing costs.

Flat-pack packaging is ideal for products that can be easily assembled by the end user. It simplifies logistics, lowers material usage and supports sustainable packaging goals. Flat packing is often used in furniture and home goods packaging applications. However, it is also effective for other items and industries that require flexible handling and reduced bulk.

Shelf-Ready Packaging

Shelf-ready packaging — also known as retail-ready packaging — combines product protection and visual impact for displays. It enables the efficient use of space by allowing products to be stocked quickly and sold directly from the container. This type of packaging design and method reduces labor costs and boosts speed to shelf. It also improves shelf visibility, helping brands stand out while protecting their product.

Common types of retail-ready packaging designs include eye-catching windowed carton packaging, captured blister packaging, vibrant retail shelf packaging and promotional packaging. Display-ready packaging is ideal for high-turnover retail spaces like grocery stores, convenience stores and shopping malls. A wide range of products use shelf-ready packaging, including toys, office supplies, snacks and beauty items.

The Benefits Of Working With Great Northern Packaging

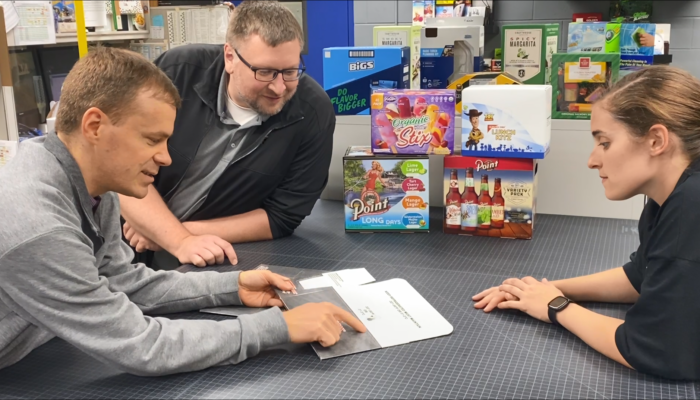

When you partner with our structural design team at Great Northern Packaging, you’ll benefit from the following:

We design our printing and packaging solutions to custom-fit your brand’s needs and objectives. Our structural design team specializes in designing one-of-a-kind, innovative packing solutions that are beautiful, structurally sound and sustainable.

Whether you need repetitive, promotional or seasonal packaging design, we offer various printing and packaging solutions at Great Northern Packaging. We help you customize solutions that suit your needs by considering your industry, brand objectives, budget, project scope and more. Great Northern will send a structural designer to your plant to understand your box erector equipment and ensure our boxes are designed for your equipment.

Contact Great Northern Packaging Today!

Design unique, innovative packaging solutions that suit your brand with Great Northern Packaging. Call 800-236-3671 or contact us online to learn more about our printing and packaging solutions today!

Get Started Today!

Tell us a few details about your product, so we can provide a solution that works for you!